Six Sigma Project Management

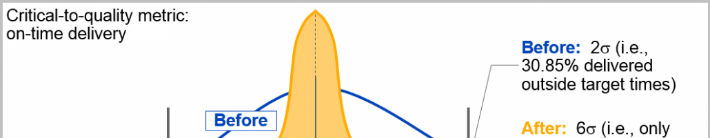

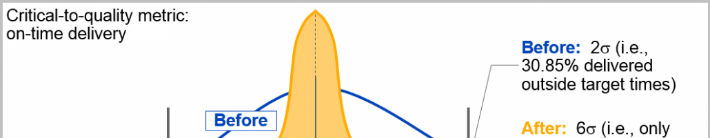

Six sigma has its roots in statistical process control. When a process operates at the six sigma level, the resulting products and services are 99.9997% defect free.

As an example for drug prescriptions, improving the process capability from 3.8 sigma (99% good) to six sigma (99.9997% good) would reduce wrong drug prescriptions from 200,000/year to 68/year.

The six sigma program has 3 key elements:

- Create standardized, disciplined problem solving approach used across company

- Drives measurement and data-driven analysis of metrics that are crucial to customers

- Focuses on reduction in variation of key metrics

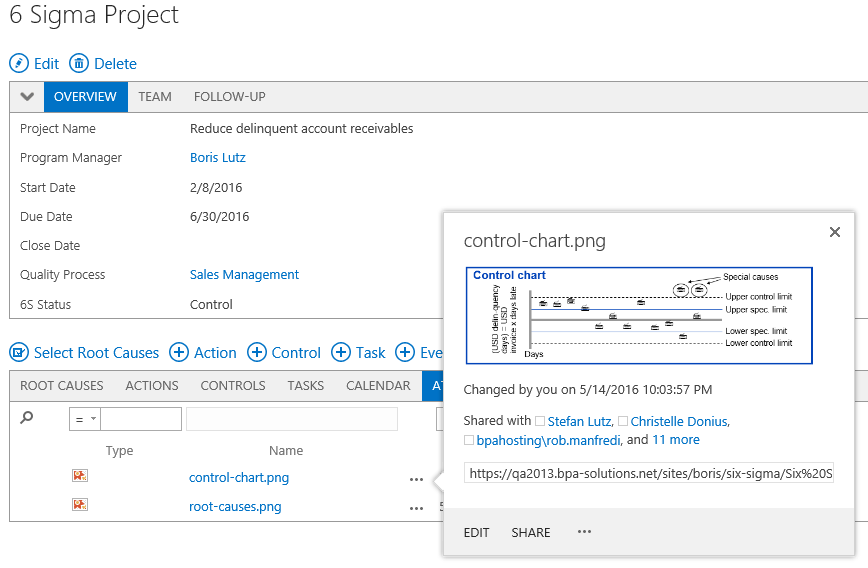

BPA allows tracking your six sigma projects based on the DMAIC methodology (Define, Measure, Analyze, Improve, Control). The visual project tracking tool gives an overview of your six sigma projects with their current DMAIC stage.

![]()

The project detail page gives a 360 degree view about your six sigma process improvement project, like the project team (black belt, green belts, etc.), selected root causes, corrective/improvement actions, controls, tasks and documents (control charts, etc.).

Like any PDCA process, key six sigma project indicators are periodically monitored, using scorecards.